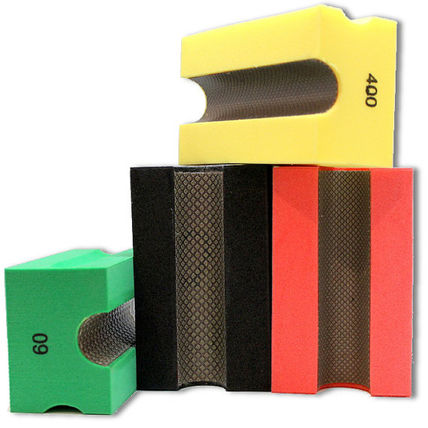

Diamond Profile Hand Polishing Pad

Unleash the potential of your stone polishing endeavors with our Diamond Profile Hand Polishing Pad, meticulously engineered for peak performance and versatility. Whether you're a seasoned stone artisan or a DIY enthusiast, this pad offers the ideal blend of durability, efficacy, and user-friendliness for all your polishing requirements.

These Diamond Profile Hand Polishing Pad offer a unique solution for customers who want to achieve a professional finish on their granite, marble, glass, or stone countertops. Designed to work in tandem with limited positions of Manual or CNC profile tools, these pads allow for precision polishing of specific areas of the profile.

With their electroplated and resin bond construction, these Pad are durable and long-lasting, ensuring that you get the most out of your investment. They come in V20 and V30 profiles, making them suitable for a range of applications, including sharp edge bullnose finishing.

Whether you prefer to work wet or dry, these pads can be used in all positions to achieve a full gloss finish. Their unique shape allows for easy maneuverability, making it easy to get into tight corners and hard-to-reach areas.

In summary, these Diamond Profile Hand Polishing pads are the perfect tool for achieving a professional finish on your countertop. With their durable construction, versatile use, and unique shape, they are a must-have for any DIY enthusiast or professional contractor.

Diameter | Size | Grit Size | Note |

V20 V30 V40 | 20mm 30mm 40mm | 60Grit-8000Grit | Full Bullnose Hand Pads |

V20 V30 V40 | 20mm 30mm 40mm | 60Grit-600Grit | "F" Ogee Hand Pads |

V20 V30 V40 | 20mm 30mm 40mm | 60Grit-600Grit | "A" Eased Hand Pads |

V20 V30 V40 | 20mm 30mm 40mm | 60Grit-600Grit | "B" Demi Bullnose |

V20 V30 V40 | 20mm 30mm 40mm | 60Grit-600Grit | "H" Dupont Hand Pads |

How to Buy

Request an Equipment Quote

Ready to buy stuff from Flexible,Request a quote now.

Become a Delare

Becoming a Flexbile Authorized Dealer

Shop

Browse Parts and equpments on our store

Solution

Flexbile solutions to help you tackle any challenge

Reviews